一次性医用耗材纸尿盆尿壶生产设备

Fully automatic industrial inner packaging paper tray forming machine

半自动纸浆模塑成型机 型号SHW-700/1000A

Semi automatic pulp molding machine SHW-700/900A

4面回转式纸浆模塑机 型号SHZG-2000

Fully automatic 4 plane rotary pulp molding machine SHZG-2000

自动成型设备,成型产品自动进入烘干线干燥。

It’s a composed of forming machine and drying line, after forming, the products will enter into drying line for drying automatically.

成型产品不需要人工中转,节省工人,生产效率高。

The forming products don’t need to be transferred by labors, so it can save labor, and has high efficiency.

可用于各种较大批量的纸模产品生产。

It is a applicable to manufacturing large quantity of pulp molding products.

全自动工业内包装纸托生产工艺流程简图

Schematic diagram of fully automatic industrial inner packaging paper tray production line

基本配置表 Basic allocation sheet

|

型号 Model |

产能 Capacity |

成型机 Forming machine |

烘干线 Drying line |

建议车间尺寸 Workshop size recommendation |

全套设备装机容量 Power requirement |

|

SHW-700A |

50-60kg/h |

往复移出式主机Reciprocating machine 模板尺寸Plate size 1600*400mm |

16m*2.6m*3m |

长度length≥30 宽度width≥10m |

100KW |

|

SHW-1000A |

80-100kg/h |

往复移出式主机Reciprocating machine 模板尺寸 plate size 1600*800mm |

26m*2.6m*3m |

长度length≥40m 宽度width≥8m |

160KW |

|

SHZG-2000A |

120-150kg/h |

4面回转式主机4 plane rotary machine 模板尺寸 plate size 1450*450mm |

26m*3.4m*3m |

长度length≥40m 宽度width≥15m |

200KW |

|

1.设备以产品干重150-200g为计算依据。 Capacity of the equipment is based on the product weight 150-200g/pc. 2.其他产能,可根据客户的试机要求专门进行设备配置。 For different capacity customized allocation according to clients’ requirement is available. 3.车间尺寸供参考,可以根据客户实际车间大小稍微调整设备布局。 Workshop size for reference only, and can be slightly adjusted according to actual size of client’s plant. |

|||||

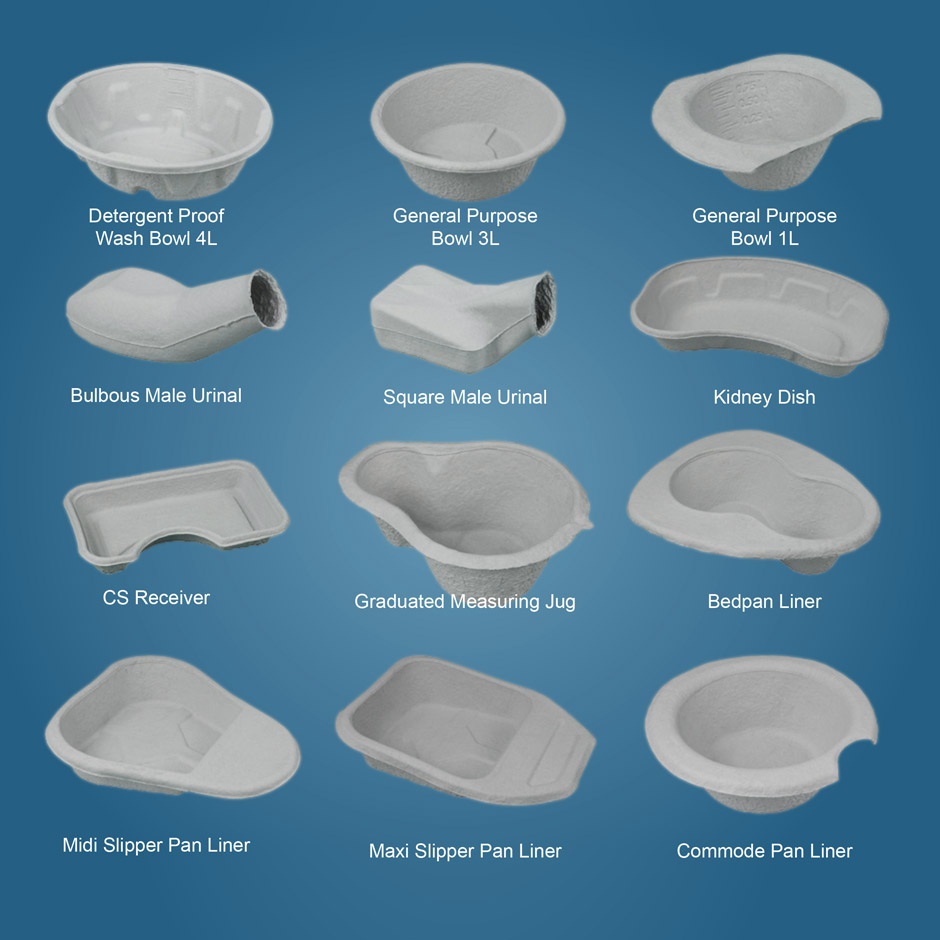

产品型号图